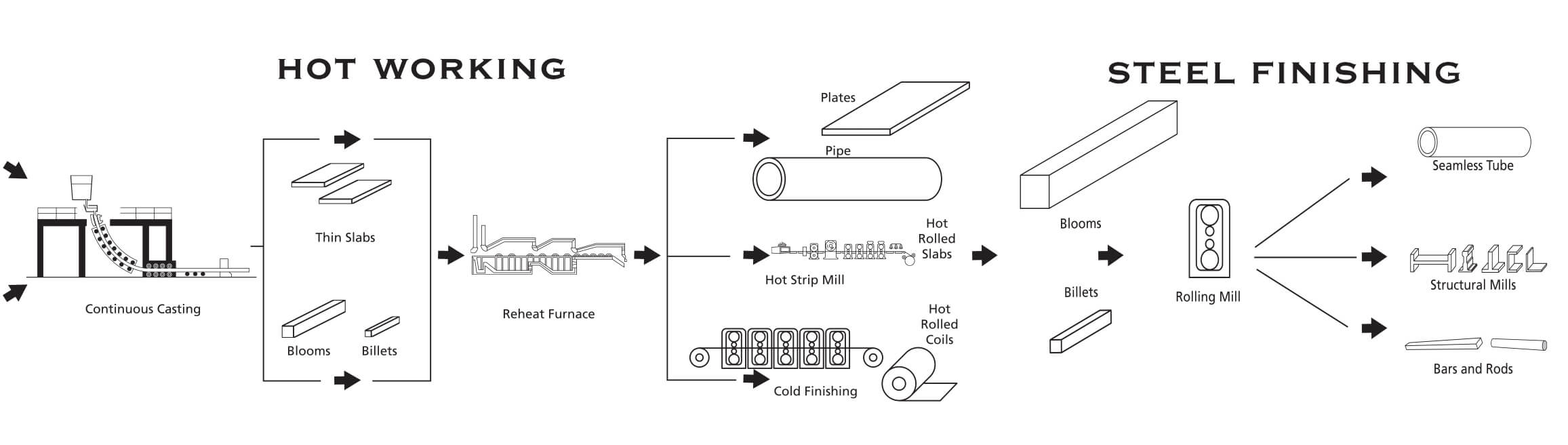

Rolling Mill Process

The primary function of a Rolling Mill is to reheat semi-finished steel billet/ Ingot nearly to their melting point, then roll them thinner and longer through successive rolling mill stands driven by motors

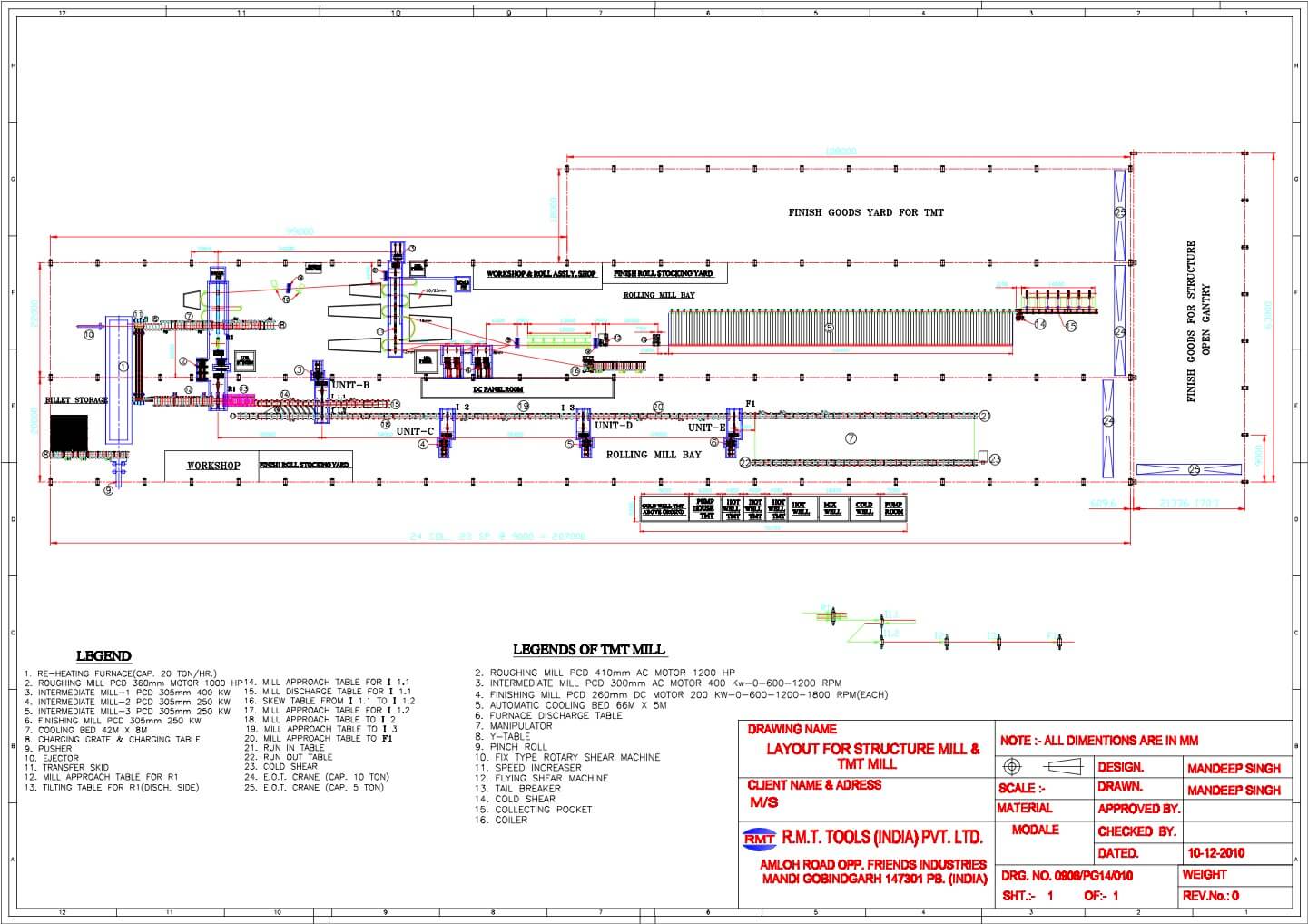

Sample Layout

Reheating

- Critical to Rolling Mill is its reheat furnace,

- Billets and Ingots are stacked on the Hot charging area of the plant with the help of overhead cranes.

- Billets placed parallel to each other on the CI lines in the furnace are continuously pushed inside the Reheating furnace with the help of mechanical or Hydraulic pusher depending on the quantity.

- The furnace is divided into number of zones (preheat, top-and-bottom; heating, top-and-bottom; and soak, top-and-bottom, east-and-west )depending on the hourly heating capacity of the Reheating furnace for temperature control.The preheat and heating zones combust a mixture of natural gas and preheated combustion

- Air with massive burners on the side walls of the furnace heat the billets nearly to its discharge temperature.

- Incoming combustion air to is heated before its fired into the furnace using the heating blowers and reccuperators

- Computer models calculate the targeted roughing mill exit temperature of the Billet to obtain a furnace discharge (‘drop-out’) aim temperature. Estimating the temperature profile through the thickness of Billet feeded in the furnace on an ongoing basis, the computer aids the operator in selecting the production rate and zone set-points that will maximize production of Billets uniformly heated to as close to the target temperature as possible

- When the Billet reaches the ‘discharge door’ at the exit end of the furnace, and the computer has determined that the Billet has been sufficiently heated, the door opens and the material is drawn out of the furnace with the help of Ejectors. The intensely hot Billet is placed on a roller table which carries it into the roughing mill.

Descaling

- After exiting the reheat furnace, the Billet passes through a descaling unit, an enclosure employing two pairs of spray headers that blast the intensely hot Billet with 1,500 psi pressurized water to remove the thick layer of oxidized iron that forms at the surface of the Billet in the oxygen-rich atmosphere of the reheat furnace.

Slitting systems

- Slitters manufactured by Rmt are highly accurate and consistent dividing. Slitters are basically used to allow rebars to be rolled in multiple strands, significantly improving the productivity of small size rebars, without increasing their finishing speeds.

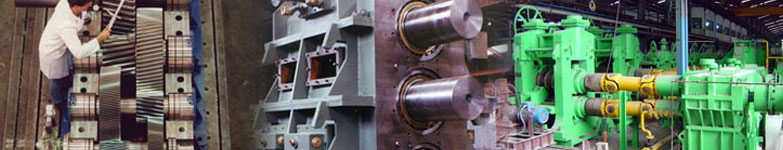

Roughing

- The roughing mill is made up of Multiple independent rolling mill stands, Billets heated in the furnace until they glow bright orange-yellow are rolled through one stand at a time to produce transfer bars suitable for finish rolling. High-pressure water-jet nozzles clean the oxidized iron, or scale, from the surface along the way.

- As the transfer bar exits the last roughing mill stand, the thickness of the leading edge of the bar is estimated. Similarly, a pyrometer measures the temperature profile of the bar from head to tail. Depending on the gauge, width, and grade of the product to be rolled. This data is collected in anticipation of finish rolling.

Cropping

- Because a square head-end is critical to properly threading the finish mills, and because an uneven tail can bruise work-roll surfaces or cause threading problems for the next production process, the head- and tail-ends of nearly every transfer bar are cropped by using crop shear, and Snap shear.

Finishing

- Hot Rolling Mills includes multiple finishing mills to reduce the thickness of the transfer bar down to the gauge according to customer’s requirement.

Flying Shear

- Flying shears are used for shearing of Reinforcement bars on the fly by synchronizing its circular speed with the linear speed of the incoming rebars on given axis.

- Flying shears are digitally operated and controlled to ensure accurate cutting as well as a digital output for providing management of the cutting mechanism.

Cooling Bed

- Used for Cooling and cross transferring the finished product towards the discharge end.

COILING or BUNDLING

- Rmt designed Edenborune type and Garret type coilers are used for obtaining a compact coil of Hot rolled bars rolled upto size of 12 mm .The hot rolled condition of the compact coil makes it suitable for direct cold working with high ductility during elastic deformation and low energy demand for final forming while while protecting the bearings from heat radiation .

- The speed of the coiler is upto 40m/sec.

Bundling

- Bundling machines are used to make bundles of the Rebar so that it could be easily lifted with the help of overhead or Mobile crane and transported

Slitting systems

- Slitters manufactured by Rmt are highly accurate and consistent dividing. Slitters are basically used to allow rebars to be rolled in multiple strands, significantly improving the productivity of small size rebars, without increasing their finishing speeds.